Jubail, Saudi Arabia, 35521

35521 الجبيل السعودية

Have Any Question

+966 550535200

Send Your Mail

info@iu-inspection.com

35521 الجبيل السعودية

+966 550535200

info@iu-inspection.com

NDT is an analysis technique used by us to evaluate the properties of materials, components, structures or systems without causing damage to the original part.

IU INSPECTION’S outstanding track record of research and development, team of highly skilled engineers and technicians, and our wide range of industrial facilities and tools place us in a unique position to solve the NDT problems of member companies. IU INSPECTION carries out hundreds of projects of this nature for our members every year.

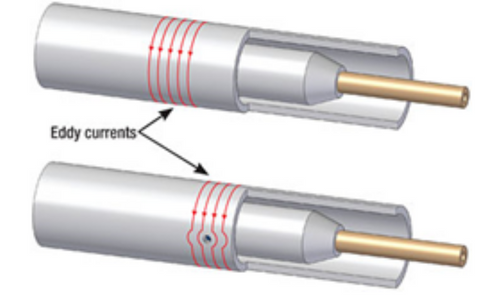

Eddy current testing is a noncontact method used to inspect non-ferromagnetic tubing. This technique is suitable for detecting and sizing metal discontinuities such as corrosion, erosion, wear, pitting, baffle cuts, wall loss, and cracks in nonferrous materials.

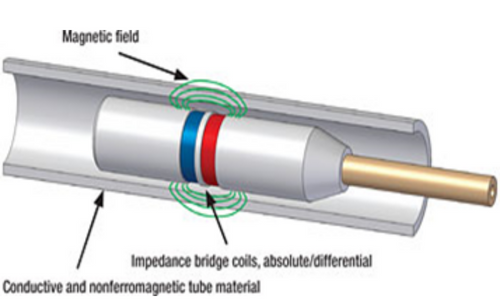

Two coils are excited with an electrical current, producing a magnetic field around them. The magnetic fields penetrate the tube material and generate opposing alternating currents in the material. These currents are called eddy currents. Any defects that change the eddy current flow also change the impedance of the coils in the probe. These changes in the impedance of the coils are measured and used to detect defects in the tube. Four simultaneous frequencies per input. This feature allows for inspection speeds up to 2 m/s with four frequencies on absolute and differential channels, without signal distortion

The MultiScan™ MS 5800E can support a large number of ECT channels to perform array probe inspections. Compared to single-channel inspection, the array probe technology allows for faster and easier surface coverage.

Remote field testing (RFT) is being used to successfully inspect ferromagnetic tubing such as carbon steel or ferrite stainless steel. This technology offers good sensitivity when detecting and measuring volumetric defects resulting from erosion, corrosion, wear, and baffle cuts.

Olympus remote field probes and the MultiScan™ MS 5800 are used all around the world to successfully inspect heat exchangers, feed water heaters, and boiler tubes.

RFT with up to four different frequencies and real-time mixes. This feature provides more flexibility for mixing and defect validation. The detection and sizing of flaws at the support plate is made easier with multi frequency inspections and dual-driver operations.

RFT with frequencies ranging from 20 Hz to 250 kHz. The high frequency available with the MultiScan MS 5800R™ extends RFT inspection to thin materials with low permeability, such as 400-series stainless steel, and other ferromagnetic alloys.

For both materials (ferrous, nonferrous)

The ultrasonic IRIS option is used to inspect a wide range of materials, including ferrous, nonferrous, and non-metallic tubing. This technique detects and sizes wall loss resulting from corrosion, erosion, wear, pitting, cracking, and baffle cuts. Olympus digital IRIS inspection technology is used extensively as a prove-up technique for remote field testing, magnetic flux leakage, and eddy current inspections.

Simplifies equipment calibration for different tube diameters and materials. The wizard also generates the reporting code for the inspection.

UT settings can be modified during the C-scan acquisition for quick optimization of signal detection.

Reduces missed flaws with C-scan displays. To enhance the quality and appearance of your reports, include color maps and cross-section views of defects.

Used to analyze data off-line, and to assess results with customers.

NFT technology uses two coils — a transmitter and a receiver. Typically, the receiver coil is close to the transmitter coil, taking advantage of the transmitter’s near-field zone — that is, the zone where the magnetic field from the transmitter coil induces strong eddy currents, axially and radially, in the tube wall. NFT probes operate within the same frequency range as RFET probes

NFT is specifically suited to detecting corrosion, erosion, and pitting inside carbon steel tubing. NFT is perfect for fin-fan tube heat exchangers because eddy currents do not go through the wall of the tube. NFT is also much more sensitive to defects close to structures such as support plates and tube sheets.

• Around 500 tubes can be inspected in 10 hrs.

• No need for an external reference coil

• Operator dependability is low

• Unaffected by structures such as support plates and Tube sheets.

• No detectability on OD side of the tube.

• Limited sensitivity to cracks

Borescope inspections are visual inspections in places inaccessible to the human eye with the help of an optical device, the borescope. It was developed in the industrial area following the success of the endoscopies in humans and animals. The borescope, also called video scope or videoboroscopio, a device is long and thin, flexible rod. Inside this tube is a telescopic system with many lenses with rotation camera, which provide a high image definition. It is also equipped with a powerful light source.

Eddy current techniques are used to nondestructively measure the thickness of nonconductive coatings on nonferrous metal substrates. A coil of fine wire conducting a high-frequency alternating current (above 1 MHz) is used to set up an alternating magnetic field at the surface of the instrument’s probe

Eddy current arrays (ECA) are the natural extension of ECT. ECAs are composed of arrays of coils that activate in sequences intended to eliminate interference between them. The array slides on top of surfaces, offering an overall wider coverage and better sensitivity to defects than conventional eddy current testing. ECA technology can detect surface-breaking defects and, to some extent, subsurface defects. ECA probes can also be shaped to match more “exotic” geometries, which enable single-pass scanning of geometries that traditionally pose serious challenges to other inspection technologies.

ECA technology is used as an alternative to other surface inspection technologies in such industries as the oil, gas, and petrochemical industry; the power generation and nuclear industries; the aerospace industry; and the heavy equipment and mining industries. ECAs also very successfully supplement ultrasonic testing (UT) and phased-array UT because these suffer from what is often referred to as a “dead zone” near the surface, making it difficult for them to detect near-surface defects. Therefore, surface applications of ECA technology are numerous, ranging from weld inspection on pressure vessels and pipes, to corrosion mapping between wing longerons and skin, by way of dovetail inspection in turbines.

The Floor map combines two distinct technologies, MFL and STARS. The introduction of STARS (Surface topology air-gap reluctance sensors) enables the scanner to determine whether there is corrosion top side, bottom side or below the surface coating.

Improved signal to noise ratio combined with STARS and MFL ensures a more accurate and efficient inspection of coated and thicker plates.

• Advanced defect sizing and classification tools

• Auditable inspection data

• Full tank floor mapping

• Full data recording

• High probability of detection

• Inspection confidence

• Field proven durability & reliability

• Motor driven

• 256 individual sensors (64 channels)

• High Resolution 4.6 x 2 mm

• Advanced signal processing and defect classification tools

• Through coating inspection up to 6 mm including FRP, GRP and SS

• USB based, simplified data transfer

• Digital calibration for different plate thicknesses

• Battery powered, no trailing cables

• Touch screen computer providing immediate plate view for defect assessment

Positive Material Identification (PMI) is one of the more specialized non-destructive testing methods. With Positive Material Identification the alloy composition of materials can be determined. If a material certificate is missing or it is not clear what the composition of a material is, then PMI offers the solution. PMI is particularly used for high-quality metals like stainless steel and high alloy metals. While engineers push the boundaries of material capacities to their limits in the design, assurance that the proper material is used becomes ever more important.

INTRODUCTION & BASIC INFORMATION

Phased Array Ultrasonic Testing (PAUT) is an advanced nondestructive examination technique that utilizes a set of ultrasonic testing (UT) probes made up of numerous small elements, each of which is pulsed individually with computer-calculated timing. more complex geometries that are difficult.

PAUT can be used for more complex geometric weld inspections, high thick materials and crack detection. Advantages are, it can be conducted more quickly, used for repeat scans because it has a high degree of repeatability, it is able to create detailed and accurate cross-sections of a part, gives a permanent record, Gives information about lateral position of defect in weld (depth and height), No radiation, higher POD.

APPLICATION

PAUT is widely used in Oil & gas, nuclear Industries (Refinery’s, Petrochemicals of piping, boilers, pressure vessels, clad material, Storage Tanks, In-service weld inspection including Stress Corrosion Cracking, Complex Geometries – Nozzles, Flanges, Shafts, bolts)

API Inspection Services

• API 510 Pressure Vessel Inspection

• API 570 Piping Inspection

• API 653 Tank Inspection

• Fitness For Service (API 579)

• Risk Based Inspection Services (API 580)

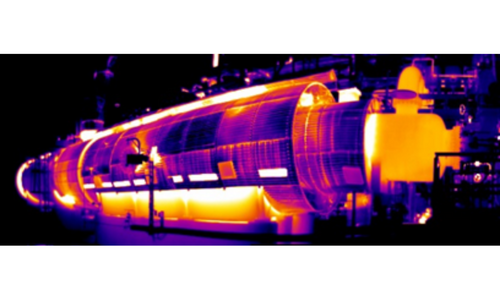

Thermography is used to measure surface temperature which aid in finding deterioration in assets and plant sites. Thermography can prevent unscheduled outcomes; improve the productivity of plant equipment and assets, increase safety and guide corrective acion. This technique is used in a variety of sectors such as power plants, petrochemical plants, refineries and steel industry, and application ranges from inspection of boiler, storage tanks, transformers etc.

Connect with us and will update you our latest project innovations